Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

General packaging products are based on the conventional size of popular products at present. The factory selects common scheme materials (such as kraft paper) for mass production. Some general packaging products do not need to go through gravure printing, so they can avoid unsalable risks and support inventory services. Generally, they are applicable to many scenarios, the starting batch is very low, and even can be distributed on behalf of one piece. Customers only need to buy self-adhesive on the back to package products Then circulation.

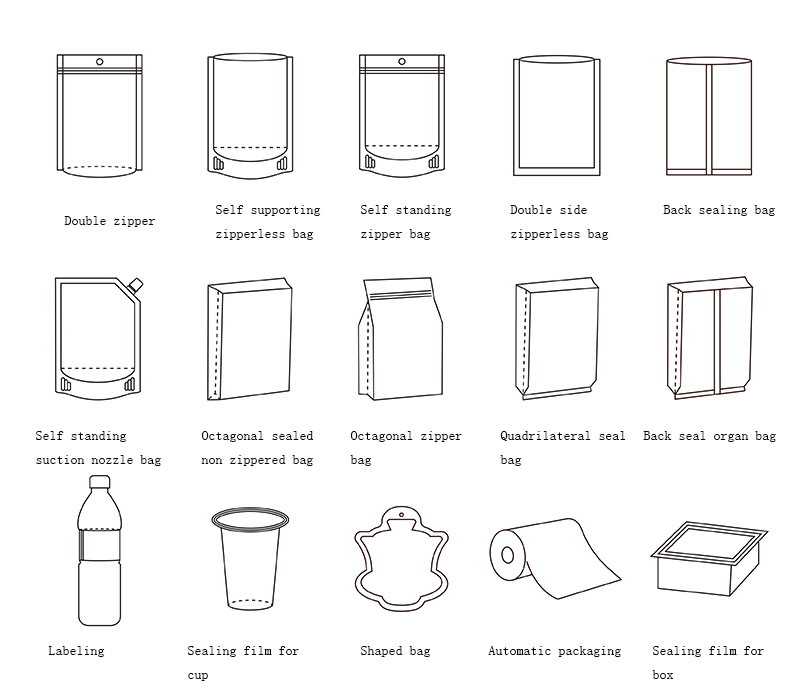

The general process of customized packaging products is: design → prepress typesetting → plate making → printing → film coating → bag making or cutting (automatic packaging). The most important step is the first step: we evaluate and analyze the customer's brand concept and product value, and design the packaging that fits the enterprise style one-to-one (such as IP characters and VI color system). Custom design can only be used by your enterprise. Try to apply for copyright to avoid infringement.

Second, the reason why customers ask how many are required is because they don't understand the principle of printing production. To put it simply, our production process is from printing, film coating to bag making. It is whole film printing, then whole film coating, and finally machine bag making on whole semi-finished film. Therefore, it can not meet the needs of "small sample" or "small batch" put forward by customers. (there are certain standards for equipment operation track, and it is impossible to interrupt any link)

About materials: gravure printing materials are facial mask (BOPP, PET, matte, pearlescent, PA, etc.), and the material of the coating process is the intima (PET, VMPET, PE, CP, etc.), and some materials can be used as printing materials or film materials. The specific scheme is analyzed in detail.

About links: the semi-finished products after printing and compounding can be put into the bag making machine only after the residual diluent and adhesive are fully volatilized in the small black room of the curing room and meet the national and industrial testing standards.

About speed: if the product has more printing color systems, the gravure master takes longer to install the plate roller. The operation speed of printing and film covering equipment is very fast, but the speed of bag making processing is adjusted according to different bag types, specific processes and size specifications, such as octagonal seal and special-shaped bag, which takes longer to make. Therefore, the delivery time usually depends on the gravure plate changing link and bag making processing link.

October 27, 2022

이 업체에게 이메일로 보내기

October 27, 2022

October 27, 2022

May 16, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.